What is the difference between galvanised steel and Corten steel? Both are strong, reliable metals that perform well in the outdoors, but what sets them apart from each other? And which of these tough steels is the right one for your project?

Galvanised steel sometimes has a mottled appearance to its surface.

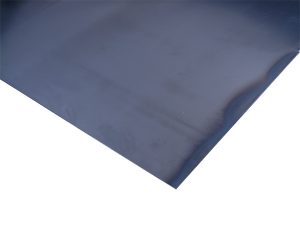

It’s easy to tell the difference between Corten steel and galvanised steel simply by looking at them. Galvanised steel is a dull, mainly matt grey and sometimes bears a mottled pattern on its surface. Corten, on the other hand, has a rust-coloured appearance. Also known as weathering steel, Corten is designed to develop a protective outer layer when it is exposed to the elements. This protective layer is what gives Corten its orange-brown colour palette and rugged good looks. But the process of weathering can take several months, so what does unweathered Corten look like? Corten in its early, unweathered state is one solid colour, a charcoal grey with a bluish tinge. Within weeks of being exposed to moisture, rust-coloured flecks begin to appear on its surface.

Unweathered Corten steel.

Weathered Corten steel.

How are they made?

Identifying galvanised and Corten steel might be relatively easy, but what is the difference in how these two metals are made? Simply put, galvanised steel is strengthened by the addition of zinc. Carbon steel is immersed in a bath of extremely hot, molten zinc. When the metal is removed from the bath and cooled down, oxygen causes a reaction that means the zinc becomes permanently bonded to the steel and a part of the steel itself, creating an alloy. Corten steel is also an alloy, and when it is produced, chromium, nickel and copper are added. Although weathered Corten looks rusty on the outside, that ‘rust’ is a protective coating that won’t penetrate the inner layers of the metal.

The Antinori nel Chianti Classico winery in Tuscany is clad in Corten steel. Photo by Fabio Santaniello Bruun on Unsplash

What are they used for?

Both galvanised steel and Corten steel are hugely popular for outdoor projects. Traditionally, galvanised steel has been used for garden items such as wheelbarrows, tools, hardware, sheds and bins. Today, it is often used for garden accessories like ponds, planters and garden edging. It is also a great option for magnetic boards, drainpipes, domestic appliances, electricity pylons, farming machinery and anywhere else where no-rust is a must.

Corten steel was originally devised in America for the building of tough railroad carriages and it is still used in containers, bridges and the shipping industry. These days, however, its unique industrial aesthetic means it has attracted the attention of architects and designers in search of a material with striking looks as well as practical plus-points. You might see Corten used in sculptures (a prime example being Antony Gormley’s Angel of the North), as cladding on buildings, or in Corten garden products such as firepits, stairs and water features.

Our galvanised steel garden edging adds a stylish edge to flower beds.

Which lasts the longest?

The choice between Corten steel and galvanised steel might seem to be down to colour; one is orange-brown and the other is silver-grey, but what about performance? If both these metals are so resistant to the elements, is one better at dealing with snow, rain, mist and ice than the other?

Although the addition of zinc makes galvanised steel strong when it comes to the weather, it will break down and begin to rust eventually. Some environmental factors like high humidity and sea salt in the air can speed up this process, but as a general rule, galvanised steel is good for around 50 years from new. The fact it is relied upon for something as important as electricity pylons is proof of just how tough this metal is.

If we look at Corten, on the other hand, we can see that the inner core of the metal is protected by that tough, rust-coloured exterior. So how long does it last? Given the fact the first Corten was only produced in the 1930s, it’s difficult to tell, but so far many buildings and sculptures made using the metal are going strong after several decades. Again, the longevity of this metal can be greatly reduced by factors such as constant humidity and exposure to sea salt in the air (many Corten shipping containers are retired after 10-15 years but go on to be used for many years away from the marine environment). If installed in an area with wet and dry cycles and not too close to the sea, Corten should last for at least 50-60 years, if not longer.

Which one is right for me?

To summarise, both Corten steel and galvanised steel are strong, reliable metals designed to stand up to the elements for decades to come. One is silver grey and one is brownish orange – which one you choose depends largely on the look you’re going for.