Accessories

Showing 13–32 of 64 results

View Details

Select options

This product has multiple variants. The options may be chosen on the product page

Brass Round Tube CZ108 is around shaped tube of CZ108 Brass Alloy.

Known as basis brass, CZ108 Brass Alloy is one of the most popular grades of brass due to its hot and cold working capabilities.

Supplied primarily as a sheet grade, this material is often used for general purpose and simple forming operations. It offers very good corrosion resistance in normal environments and good machinability at slow speeds.

• Specifications

CZ108 (CW508L) Basic Brass

• Characteristics

o Corrosion Resistance: Good

o Cold Working: Excellent

o Hot Working: Fair

o Weldability: Excellent

• Uses

Common uses of Brass Round Tube CZ108 include:

o Scientific Applications

o Radiators

o Heat Exchangers

o Decorative

• More Info

o Density = 8.44 g/cm³

o Melting Point = 916 °C

o Thermal Expansion = 20.5 x10^-6 /K

o Modulus of Elasticity = 103.4 GPa

o Thermal Conductivity = 116 W/m.K

o Tensile Strength = 440 Min MPa

o Hardness Vickers = 115 Min HV

o Proof Stress = 320 Min MPa

o Hardness Brinell = 110 Min HB

o Elongation A = 10 Min %

Brass Round Tube CZ108

£55.07 – £289.00Product Weight: 25kg

View Details

Select options

This product has multiple variants. The options may be chosen on the product page

Brass Round Tube CZ121 is a round shaped tube of CZ121 Brass Alloy.

CZ121 Brass Alloy is a free-machining brass consisting of a duplex phase structure with a 3% lead content.

It is suited to high speed machining operations due its superior machinability, thread rolling and knurling characteristics.

Particles of lead are finely dispersed throughout the microstructure, acting as both a lubricant and a chip breaker to give the alloy its free-machining characteristics.

CZ121 Brass Alloy’s machinability rating of 100 is the standard against which all copper alloys are rated. It offers good strength, is easily soldered or brazed and has good resistance to corrosion.

• Specifications

CZ121 (CW614N) Free Machining Brass

• Characteristics

o Corrosion Resistance: Excellent

o Cold Working: Poor

o Hot Working: Excellent

o Heat Treatment: Good

o Machinability: Excellent

o Weldability: Excellent

• Uses

Common uses of Brass Round Tube CZ121 include:

o High Speed Machined Components

o Architectural Extrusions

o Locks

o Hinges

• More Info

o Density = 8.47 g/cm³

o Melting Point = 875 °C

o Thermal Expansion = 20.9 x10^-6 /K

o Modulus of Elasticity = 97 GPa

o Thermal Conductivity = 123 W/m.K

o Electrical Resistivity = 0.062 x10^-6 Ω .m

o Proof Stress = 220 - 350 MPa

o Tensile Strength = 360 - 500 MPa

o Hardness Brinell = 90 - 160 HB

o Elongation A = 20 - 5 %

Brass Round Tube CZ121

£116.98 – £191.89Product Weight: 25kg

View Details

Select options

This product has multiple variants. The options may be chosen on the product page

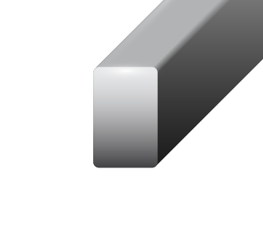

Brass Square Bar CZ121 is a square shaped CZ121 Brass Alloy bar.

CZ121 Brass Alloy is a free-machining brass consisting of a duplex phase structure with a 3% lead content.

It is suited to high speed machining operations due its superior machinability, thread rolling and knurling characteristics.

Particles of lead are finely dispersed throughout the microstructure, acting as both a lubricant and a chip breaker to give the alloy its free-machining characteristics.

CZ121 Brass Alloy’s machinability rating of 100 is the standard against which all copper alloys are rated. It offers good strength, is easily soldered or brazed and has good resistance to corrosion.

• Specifications

CZ121 (CW614N) Free Machining Brass

• Characteristics

o Corrosion Resistance: Excellent

o Cold Working: Poor

o Hot Working: Excellent

o Heat Treatment: Good

o Machinability: Excellent

o Weldability: Excellent

• Uses

Common uses of Brass Square Bar CZ121 include:

o High Speed Machined Components

o Architectural Extrusions

o Locks

o Hinges

• More Info

o Density = 8.47 g/cm³

o Melting Point = 875 °C

o Thermal Expansion = 20.9 x10^-6 /K

o Modulus of Elasticity = 97 GPa

o Thermal Conductivity = 123 W/m.K

o Electrical Resistivity = 0.062 x10^-6 Ω .m

o Proof Stress = 220 - 350 MPa

o Tensile Strength = 360 - 500 MPa

o Hardness Brinell = 90 - 160 HB

o Elongation A = 20 - 5 %

Brass Square Bar CZ121

£0.00 – £954.49Product Weight: 25kg

View Details

Select options

This product has multiple variants. The options may be chosen on the product page

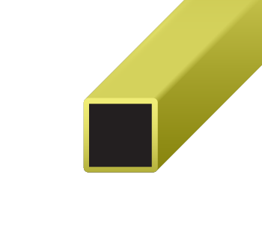

Brass Square Tube CZ108 is a square shaped tube of CZ108 Brass Alloy.

Known as basis brass, CZ108 Brass Alloy is one of the most popular grades of brass due to its hot and cold working capabilities.

Supplied primarily as a sheet grade, this material is often used for general purpose and simple forming operations. It offers very good corrosion resistance in normal environments and good machinability at slow speeds.

• Specifications

CZ108 (CW508L) Basic Brass

• Characteristics

o Corrosion Resistance: Good

o Cold Working: Excellent

o Hot Working: Fair

o Weldability: Excellent

• Uses

Common uses of Brass Square Tube CZ108 include:

o Scientific Applications

o Radiators

o Heat Exchangers

o Decorative

o

• More Info

o Density = 8.44 g/cm³

o Melting Point = 916 °C

o Thermal Expansion = 20.5 x10^-6 /K

o Modulus of Elasticity = 103.4 GPa

o Thermal Conductivity = 116 W/m.K

o Tensile Strength = 440 Min MPa

o Hardness Vickers = 115 Min HV

o Proof Stress = 320 Min MPa

o Hardness Brinell = 110 Min HB

o Elongation A = 10 Min

Brass Square Tube CZ108

£71.83 – £208.90Product Weight: 25kg

View Details

Select options

This product has multiple variants. The options may be chosen on the product page

Brass Square Tube CZ121

Brass Square Tube CZ121 is a high-quality, free-machining brass alloy known for its exceptional machinability and strength. This square-shaped brass tube is a versatile metal product widely used in both commercial and domestic applications. With a duplex phase structure and 3% lead content, CZ121 brass square tube offers outstanding performance in high-speed machining operations, making it ideal for precision engineering. CZ121 square brass tube is designed for thread rolling, knurling, and other machining techniques, thanks to its finely dispersed lead particles that act as a lubricant and chip breaker during processing. With a machinability rating of 100, CZ121 brass is the industry benchmark for copper alloys. At Buy Metal Online, we supply brass square tubes in various sizes to meet your project needs. Whether you're involved in large-scale manufacturing or specialized industrial applications, our high-quality brass tubing is a reliable choice.Key Qualities of Brass Square Tube

CZ121 brass square tubes are engineered for performance, durability, and precision. The alloy offers excellent hot formability, good strength, and is easily soldered or brazed. However, cold working is not recommended due to its poor cold workability. Specification: CZ121 (CW614N) Free Machining BrassKey Characteristics:

- • Corrosion Resistance: Excellent

- • Cold Working: Poor

- • Hot Working: Excellent

- • Heat Treatment: Good

- • Machinability: Excellent

- • Weldability: Excellent

Physical Properties:

- • Density: 8.47 g/cm³

- • Melting Point: 875°C

- • Thermal Expansion: 20.9 x10⁻⁶/K

- • Modulus of Elasticity: 97 GPa

- • Thermal Conductivity: 123 W/m.K

- • Electrical Resistivity: 0.062 x10⁻⁶ Ω.m

- • Proof Stress: 220 – 350 MPa

- • Tensile Strength: 360 – 500 MPa

- • Hardness (Brinell): 90 – 160 HB

- • Elongation A: 20 – 5%

Benefits of CZ121 Brass Square Tube

The CZ121 brass square tube offers a range of benefits that make it ideal for various industries and applications:- • Exceptional Machinability: With a machinability rating of 100, CZ121 brass is the industry standard for copper alloys, ensuring efficient and precise machining.

- • Strength and Durability: Its robust structure makes it ideal for structural frameworks and architectural projects.

- • Corrosion Resistance: CZ121 brass provides excellent resistance to moisture, air, and corrosive environments, ensuring long-term performance.

- • Versatile Applications: The combination of strength, machinability, and corrosion resistance makes CZ121 brass suitable for both commercial and domestic projects.

- • Aesthetic Appeal: The rich golden hue of brass offers a decorative finish, ideal for creative and ornamental designs.

Popular Uses for Brass Square Tube CZ121

Thanks to its impressive strength, machinability, and corrosion resistance, CZ121 brass square tube is widely used in various industries. Common applications include:- • Structural Support: Brass square tubes can be used as beams, columns, or frames in various structures due to their strength and durability.

- • High-Speed Machined Components: Brass square tubes are used in the manufacturing of various machine components, ideal for precision parts where accuracy and detail are crucial.

- • Architectural Extrusions: Used for frameworks, decorative trims, and structural designs.

- • Locks and Hinges: The strength and durability of CZ121 brass make it ideal for manufacturing secure and reliable fixtures.

- • Fixtures and Furniture: They are used in fixtures and furniture to add colour, stability, and enhanced durability.

- • Automotive: Brass square tubes are used in automotive applications for brake lines, fuel lines, and exhaust systems.

Order Brass Square Tube from Buy Metal Online

At Buy Metal Online, we supply premium-quality CZ121 brass square tubes in various sizes to suit your project requirements. Enjoy free UK delivery on orders over £100, plus take advantage of 10% off orders over £100 or 5% off your first purchase. Choose Buy Metal Online for reliable service, high-quality materials, and fast delivery. Order your brass square tube today and complete your project with confidence!Why buy from Buy Metal Online?

Brass Square Tube CZ21

£0.00 – £229.26Product Weight: 25kg

View Details

Select options

This product has multiple variants. The options may be chosen on the product page

Brass Tee Bar CZ121 is a tee shaped CZ121 Brass Alloy bar.

CZ121 Brass Alloy is a free-machining brass consisting of a duplex phase structure with a 3% lead content.

It is suited to high speed machining operations due its superior machinability, thread rolling and knurling characteristics.

Particles of lead are finely dispersed throughout the microstructure, acting as both a lubricant and a chip breaker to give the alloy its free-machining characteristics.

CZ121 Brass Alloy’s machinability rating of 100 is the standard against which all copper alloys are rated. It offers good strength, is easily soldered or brazed and has good resistance to corrosion.

• Specifications

CZ121 (CW614N) Free Machining Brass

• Characteristics

o Corrosion Resistance: Excellent

o Cold Working: Poor

o Hot Working: Excellent

o Heat Treatment: Good

o Machinability: Excellent

o Weldability: Excellent

• Uses

Common uses of Brass Tee Bar CZ121 include:

o High Speed Machined Components

o Architectural Extrusions

o Locks

o Hinges

• More Info

o Density = 8.47 g/cm³

o Melting Point = 875 °C

o Thermal Expansion = 20.9 x10^-6 /K

o Modulus of Elasticity = 97 GPa

o Thermal Conductivity = 123 W/m.K

o Electrical Resistivity = 0.062 x10^-6 Ω .m

o Proof Stress = 220 - 350 MPa

o Tensile Strength = 360 - 500 MPa

o Hardness Brinell = 90 - 160 HB

o Elongation A = 20 - 5 %

Brass Tee Bar CZ121

£0.00 – £238.60Product Weight: 25kg

View Details

Select options

This product has multiple variants. The options may be chosen on the product page

Bright Zinc Plated Hexagon Nuts with a nylon insert which 'grabs' onto the bolt threads giving a greater resistance against the nut loosening from the bolt. Good for use where the nut is used in areas of high vibration.

We supply the nuts in packs of 5, 10, 25, 50 and 100 - great for use with our screwed rod. In sizes M6, M8, M10, M12 and M16.

M6 = 6mm thread

M8 = 8mm thread

M10 = 10mm thread

M12 = 12mm thread

M16 = 16mm thread

BRIGHT ZINC PLATED NYLON INSERT NUTS

£2.90 – £16.74

View Details

Select options

This product has multiple variants. The options may be chosen on the product page

We supply packs containing cap head screws, nuts and washers in quantities of either 5, 10 or 20.

M6 = 6mm thread

M8 = 8mm thread

M10 = 10mm thread

M12 = 12mm thread

An Example is M6 x 20 = 6mm diameter thread with the length being 20mm

Cap head screws, nuts and washers

£1.09 – £13.29

View Details

Select options

This product has multiple variants. The options may be chosen on the product page

Engineering Steel Flat Keystock EN8 is a flat shaped keystock of EN8 Engineering Steel.

EN8 Engineering Steel is usually supplied untreated but can be supplied to order in the normalized or finally heat treated (quenched and tempered to “Q” or “R” properties for limiting ruling sections up to 63mm), which is adequate for a wide range of applications.

EN8 is a very popular grade of through-hardening medium carbon steel, which is readily machinable in any condition. (Refer to our machinability guide). EN8 is suitable for the manufacturing of parts such as general-purpose axles and shafts, gears, bolts and studs.

| Specifications 080M40 |

| Characteristics Hardening: Fair Heat Treatment: Good Machinability: Good Welding: Poor |

| Uses Common uses of Engineering Steel Flat Keystock EN8 include: Axles Automotive Parts Bolts Connecting Rods General Engineering Components Studs Spindles |

| More Info Elongation: 16% Hardness: 201 - 255 HB Max Stress: 700 - 850 N/mm2 Yield Stress: 465 N/mm2 |

Engineering Steel Flat Keystock EN8

£56.28 – £644.97Product Weight: 15kg

View Details

Select options

This product has multiple variants. The options may be chosen on the product page

Engineering Steel Hexagon Bar EN16 is a hexagon-shaped alloy bar with six equal sides, known for its high tensile strength and excellent mechanical properties. Commonly supplied as EN16T to the BS970 specification, this low-alloy steel offers outstanding ductility, machinability, and shock resistance. It’s an alternative to other high tensile chromium and nickel-chromium steel grades and is widely used across multiple industries, including automotive, construction, and manufacturing.

At Buy Metal Online, our EN16 engineering steel hexagonal bars are available in 1000mm lengths and a range of sizes, making them suitable for various applications. If you require specific sizes, please get in touch to discuss your requirements.

Key Characteristics of Engineering Steel Hexagon Bar EN16

Our EN16 engineering steel hexagon bar has six equal sides, with a combination of excellent machinability and high tensile strength that makes it ideal for industries requiring components that can withstand high stress and pressure. EN16 is more resistant to shear loading and frictional wearing than EN8, and generally has a higher corrosion resistance and better weldability in comparison. When hardened and tempered to "T" condition (EN16T), it becomes highly machinable, making it a popular choice in engineering applications.Key specifications include:

- Specification: 605M36T

- Elongation: 13%

- Hardness: 248 - 302 HB

- Tensile Strength: 850 - 1000 N/mm²

- Yield Strength: 680 N/mm²

- Corrosion Resistance: Good

- Heat Treatment: Good

- Machinability: Good

- Weldability: Fair

Benefits of Engineering Steel Hexagon Bar EN16

The EN16 engineering steel hexagonal bar offers a range of benefits that make it suitable for use in demanding environments:- High Tensile Strength: The bar’s high tensile strength ensures it can handle heavy loads without compromising on structural integrity, making it ideal for high-performance applications.

- Good Ductility: The ductility of engineering steel hexagon bar EN16 means it can be drawn into wire or other forms without breaking, allowing for flexibility in manufacturing processes. The material also offers relief from temper brittleness, meaning that it does not lose ductility under heat treatment processes.

- Shock Resistance: Known for its excellent shock resistance, EN16 engineering steel hexagon bars are particularly suited for applications that involve high impact, ensuring safety and durability.

- Corrosion Resistance: EN16 engineering steel has good resistance to corrosion and is therefore suitable for use in outdoor and industrial environments where the material is exposed to moisture and corrosive agents.

- Durability: The corrosion resistance and durability of this material enhances the longevity of components and structures, making it a cost-effective choice for long-term applications.

- Machinability: This low alloy steel is highly machinable which allows for easy precision shaping, cutting and fabrication, reducing production time and improving efficiency.

Popular Uses for Engineering Steel Hexagon Bar EN16

EN16 engineering steel hexagonal bars are a popular 'all-rounder' and are used in a wide variety of general engineering applications, particularly where high shock resistance is required.- Automotive Industry: Often used in the production of vehicle components such as axles, crankshafts, suspension systems, and gears, where high strength and impact resistance are essential.

- Manufacturing and Machinery: The EN16 engineering steel hexagon bar is ideal for manufacturing tools, machinery components, and high-stress equipment parts that require durability and the ability to withstand mechanical strain.

- Construction: In construction, EN16 hexagonal steel bars are used in the creation of structural frameworks, high-strength bolts, and reinforcement bars, contributing to the overall stability and strength of buildings, bridges and other infrastructure.

- General Engineering: EN16 is also commonly used in general engineering applications, including lifting gears, connection rods, and high-tensile shafts, where the material’s resilience and ductility are highly valued.

Common uses include:

- Axles

- Nuts and bolts

- Connection rods

- Crankshafts

- High load couplings

- Hubs

- Lifting gears

- Pistons

- Shafts

Engineering Steel Hexagon Bar EN16 from Buy Metal Online

At Buy Metal Online, we provide high-quality EN16 engineering steel hexagon bars at competitive prices. We offer free UK delivery and 10% off on orders over £100, giving you the best value for money for your projects. Order from Buy Metal Online and enjoy 5% off your first purchase when you shop with us!Why buy from Buy Metal Online?

Engineering Steel Hexagon Bar EN16

£0.00 – £137.40Product Weight: 15kg

View Details

Select options

This product has multiple variants. The options may be chosen on the product page

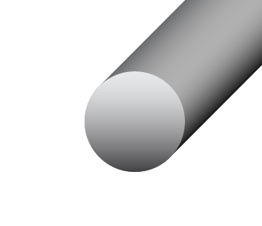

Engineering steel round bar EN16 is a round-shaped EN16 engineering steel alloy bar. It is a versatile low alloy, high tensile steel that’s known for its ductility and shock resistance. EN16 engineering steel alloy is commonly supplied as EN16T to the BS970 specification and can be used for countless industrial projects.

Made from premium-grade materials, it offers unmatched durability and performance. EN16 is an alternative alloy steel grade to other chromium and nickel-chromium high tensile steel specifications.

Key characteristics of EN16 Engineering Steel Round Bar

Our EN16 Engineering Steel Round Bar is generally more resistant to shear loading and frictional wearing than our EN8 Engineering Steel Round Bar, and has a higher corrosion resistance and better weldability in comparison. EN16 engineering steel alloy is commonly hardened and tempered to “T” condition (EN16T) which is readily machineable. Take a look at its properties and characteristics below…- Specifications: 605M36T

- Elongation: 13%

- Hardness: 248 – 302 HB

- Tensile: 850 – 1000 N/mm²

- Yield: 680 N/mm²

- Corrosion Resistance: Good

- Heat Treatment: Good

- Machinability: Good

- Weldability: Fair

Benefits of Engineering Steel Round Bar EN16

Supplied as a round bar, EN16 engineering steel has good mechanical properties and shock resistance, and is readily machinable for use in a wide range of general engineering applications. EN16 engineering steel round bars are regarded as a popular ‘all-rounder’ when it comes to engineering. Ductility: EN16 engineering steel round bar offers excellent ductility, allowing it to be stretched or pulled into wire without breaking. The material offers relief from temper brittleness, meaning that EN16 engineering steel does not lose ductility under heat treatment processes. Shock Resistance: One of the key benefits of EN16 engineering steel is its excellent ability to absorb and dissipate shock effectively. This makes it particularly well-suited for applications subject to sudden impacts, providing added safety and reliability. Strength: EN16 engineering steel round bars have good strength and resilience, making them capable of withstanding heavy loads and high levels of stress without compromising on structure. Corrosion Resistance: Many engineering steel alloys, including EN16, exhibit excellent resistance to corrosion, rust, and degradation in challenging environments. This corrosion resistance and durability enhances the longevity of components and structures, making EN16 engineering steel round bar a cost-effective choice for long-term applications. Machinability: Engineering steel round bar EN16 has great machinability, allowing for easy shaping, cutting, and fabrication processes. This increases efficiency in manufacturing, enabling precise customisation and complex designs with ease.Common Uses for EN16 Engineering Steel Round Bar

There are many uses for EN16 engineering steel round bars, particularly in applications that require high shock resistance. Automotive: EN16 engineering steel round bar is extensively used in the automotive sector for manufacturing components such as axles, bolts, crankshafts, suspension systems, and gears. Its high strength, durability, and shock resistance ensure reliable performance in vehicles subject to demanding operating conditions. Manufacturing and Machinery: Various manufacturing industries rely on EN16 engineering steel round bar for producing machinery components, tools, and equipment. Its versatility, machinability, and resistance to wear make it an essential material for manufacturing processes across different sectors. Construction: EN16 engineering steel round bar is a staple material in construction for structural frameworks, reinforcement bars and bolts. Its exceptional strength and durability contribute to the stability of buildings, bridges, and other infrastructure projects. Common uses include:- Axles

- Nuts and bolts

- Connection rods

- Crankshafts

- High load couplings

- Hubs

- Lifting gears

- Pistons

- High tensile shafts

EN16 Engineering Steel Round Bar from Buy Metal Online

Buy your EN16 engineering steel round bar from Buy Metal Online today for the best quality at competitive prices. We also offer a 10% discount and free UK delivery on orders over £100, making it easier than ever to access the materials you need for your projects. EN16 engineering steel round bar is a reliable and versatile solution for a wide range of uses. With its exceptional ductility and shock resistance, it's the material of choice for a variety of general engineering applications. Trust Buy Metal Online for superior quality, unbeatable value, and exceptional customer service. Have a question? Contact us!Engineering Steel Round Bar EN16

£40.71 – £380.65Product Weight: 15kg

View Details

Select options

This product has multiple variants. The options may be chosen on the product page

Engineering Steel Round Bar EN19 is a round shaped EN19 Engineering Steel Alloy bar.

EN19 Engineering Steel Alloy is also known as 709M40.

It is a high quality alloy steel, renowned for its good ductility, shock resistance and its resistance to wear properties. It is suitable for gears, pinions, shafts, spindles,; it is now also widely used in the oil and gas industry

| Specifications 709M40T |

| Characteristics Corrosion Resistance: Fair Hardening: Good Machinability: Fair Weldability: Good |

| Common uses of Engineering Steel Round Bar EN19 include: Automotive Gears & Parts Load Bearing Tie Rods Oil & Gas Industry Applications Shafts Towing Pins |

| More Info Elongation: 13% Hardness: 248 - 302 HB Tensile: 850-1000 N/mm² Yield: 680 N/mm² |

Engineering Steel Round Bar EN19

£53.38 – £624.91Product Weight: 15kg

View Details

Select options

This product has multiple variants. The options may be chosen on the product page

Engineering Steel Round Bar EN24 is a high-strength engineering steel alloy bar designed for demanding applications requiring exceptional toughness, durability, and wear resistance. EN24 steel can achieve a much deeper hardenability than 4100 series steels, enabling high strength in heavy sections while maintaining maximum toughness and ductility. With a high fatigue/tensile ratio, EN24 maintains its strength, flexibility, and impact resistance at relatively high temperatures. It also boasts excellent non-distorting properties, making it ideal for precision engineering.

At Buy Metal Online, we supply EN24 engineering steel round bars in 1000mm lengths and a range of sizes, all treated in the T condition to enhance its mechanical properties. If you have specific size requirements, contact us to discuss your needs.

Key Qualities of Engineering Steel Round Bar EN24

EN24T is highly regarded for its wear resistance and is often chosen for applications that demand exceptional strength and performance. Thanks to its impressive mechanical properties, EN24T is a popular choice in industries where high-strength components are essential. Specification: 817M40TKey Characteristics:

- • Corrosion Resistance: Fair

- • Heat Treatment: Very Good

- • Machinability: Good

Physical Properties:

- • Elongation: 13%

- • Hardness: 248 – 302 HB

- • Tensile Strength: 850 – 1000 N/mm²

- • Yield Strength: 680 N/mm²

Benefits of Engineering Steel Round Bar EN24

The EN24 engineering steel round bar offers a combination of high strength, durability, and machinability, making it ideal for industries that require reliable and long-lasting materials.- • Excellent Mechanical Properties: EN24 provides outstanding strength, toughness, and impact resistance, ensuring durability in demanding environments.

- • Wear Resistance: EN24T is designed to withstand abrasion and heavy stress, making it perfect for moving parts and high-impact applications.

- • Good Machinability: Despite its strength, EN24T is easy to machine, allowing for efficient fabrication and precise engineering.

- • Versatile Applications: Suitable for both commercial and domestic projects, EN24 steel round bar is a practical choice for professionals and DIY enthusiasts alike.

Popular Uses for Engineering Steel Round Bar EN24

Thanks to its high strength, resistance to wear, and good machinability, EN24 steel round bar is widely used across multiple industries. Common applications include:- • Drill Bushings: Precision parts that require strength and wear resistance.

- • Gears: Ideal for high-performance gears in machinery and vehicles.

- • High Strength Shafts: Used in engineering and automotive industries where durability is crucial.

- • Punches and Dies: EN24’s toughness makes it ideal for tooling and manufacturing applications.

- • Retaining Rings: Provides a secure and durable fastening solution in heavy-duty machinery.

Order EN24 Engineering Steel Round Bar from Buy Metal Online

At Buy Metal Online, we supply premium EN24 engineering steel round bars in a range of sizes with a best price guarantee, available in 1000mm lengths and treated in the T condition for enhanced strength and durability. Enjoy free UK delivery on orders over £100, plus 10% off when you spend £100+ or 5% off your first purchase with us. Choose Buy Metal Online for high-quality materials, expert advice, and fast, reliable delivery. Order your EN24 steel round bars today and get started on your next project with confidence!Why buy from Buy Metal Online?

Engineering Steel Round Bar EN24

£66.00 – £428.41Product Weight: 15kg

View Details

Select options

This product has multiple variants. The options may be chosen on the product page

Engineering Steel Round Bar EN8 is a round shaped EN8 Engineering Steel bar.

EN8 Engineering Steel is usually supplied untreated but can be supplied to order in the normalized or finally heat treated (quenched and tempered to “Q” or “R” properties for limiting ruling sections up to 63mm), which is adequate for a wide range of applications.

EN8 is a very popular grade of through-hardening medium carbon steel, which is readily machinable in any condition. (Refer to our machinability guide). EN8 is suitable for the manufacturing of parts such as general-purpose axles and shafts, gears, bolts and studs.

| Specifications 080M40 |

| Characteristics Hardening: Fair Heat Treatment: Good Machinability: Good Welding: Poor |

| Uses Common uses of Engineering Steel Round Bar EN8 include: Axles Automotive Parts Bolts Connecting Rods General Engineering Components Studs Spindles |

| More Info Elongation: 16% Hardness: 201 - 255 HB Max Stress: 700 - 850 N/mm2 Yield Stress: 465 N/mm2 |

Engineering Steel Round Bar EN8

£26.04 – £576.13Product Weight: 15kg

View Details

Add to basket

Fixing kit for use with our range of splashbacks, magnetic boards and unbreakable mirrors.

Each fixing kit contains:

4 of each of the following - 4.25mm diameter x 25mm long wood screws, rawl plugs and satin dome screw covers.

Fixing Kit

£8.82

View Details

Select options

This product has multiple variants. The options may be chosen on the product page

Mild Steel Angle Galvanised is an angle shaped galvanised Mild Steel.

Hot-dip galvanising is the process of coating iron or steel with a thin zinc layer, by passing the steel through a molten bath of zinc at a temperature of around 860 °F (460 °C). When exposed to the atmosphere, pure zinc reacts with oxygen to form zinc oxide, which further reacts with carbon dioxide to form zinc carbonate, a dull grey, fairly strong material that stops further corrosion in many circumstances, protecting the steel below from the elements.

Galvanised steel is widely used in applications where rust resistance is needed, and can be identified by the crystallization patterning on the surface (often called a “spangle”).