Shopping

This category is used to include products in the shopping feed.

Showing 1–16 of 106 results

ALUMINIUM 6063T6 ANGLE

£26.90 – £170.00ALUMINIUM 6082 ANGLE

£28.10 – £90.10Aluminium Channel 6063T6

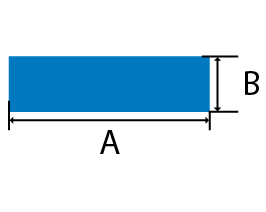

£133.66 – £309.71Aluminium Flat Bar 6063T6

£23.10 – £118.58Aluminium Flat Bar 6082T6

£23.70 – £273.84Aluminium Round Tube 6063T6

£21.44 – £48.21Aluminium Round Tube 6082T6

£29.77 – £51.02Brass Angle CZ121

£45.00 – £250.00Brass Angle CZ130

£55.00 – £105.00Brass Channel CZ121

£49.90 – £149.70Product Weight: 15kg

Brass Flat Bar CZ121

£0.00 – £850.20Brass Half Round Bar CZ121

£0.00 – £82.91Product Weight: 15kg

Brass Hexagon Bar CZ121

£59.59 – £393.88Product Weight: 25kg

Brass Round Tube CZ108

£55.07 – £289.00Product Weight: 25kg

Brass Round Tube CZ121

£116.98 – £191.89Product Weight: 25kg

Brass Square Bar CZ121

£0.00 – £954.49Product Weight: 25kg