Free Cutting Service

Best Price Guarantee

10% Off £100+ Orders

5% Off First Order

Free Parcel Del. Over £100

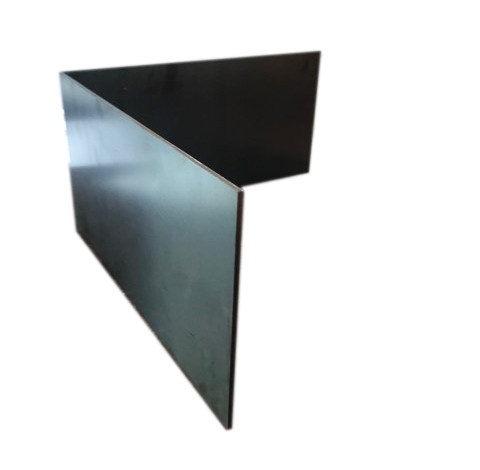

Welding Rods – For Use With Corten Steel 4KG Pack

Buying Options

Additional Information

Mild Steel Welding Rods 3.2mm – E6818-W2 4kg Pack

If you want to read what the manufacturer says then read below but if you want the overview then this bit is for you. The MacTrode E6818-W2 rod is a low hydrogen MMA rod that is designed specifically for weathering steels such as Corten.

Because of the above if you get these rods damp and require to rebake them then it does require a higher heat for a slightly longer than normal time. 300 to 350 degrees C for 1 to 2 hours.

These rods are made in the UK.

A low hydrogen, basic flux coated electrode on a low carbon mild steel core wire with an extruded moisture resistant chemically basic flux which has controlled iron powder addition. The moisture resistant coating gives a very low weld metal hydrogen levels. The electrode recovery rate in respect to the core wire is approx. 120%. Smooth arc, low spatter, easy strike and restrike. The electrode is mainly used for weathering steels containing a similar controlled addition & is claimed to offer a threefold improvement in corrosion resistance compared with plain C, Mn steels. The weld metal also resists preferential corrosion in sea water, particularly in arctic waters high in oxygen & salinity,

& has applications for welding micro alloys & carbon manganese steels in ice breaker vessels & offshore structures. Applications also include architectural structures, bridges & exhaust gas flues. Materials to be welded include Corten A, B1 (b. steel, US Steels) and other proprietary designations. BS4360 Grade WR50A to WR50C, ASTM A588 Grades A, B, C, K. Din 1.8960, 1.8961, 1.8963.

Mild Steel Welding Rods 2.5mm – E6818-W2 4kg Pack

If you want to read what the manufacturer says then read below but if you want the overview then this bit is for you. The MacTrode E6818-W2 rod is a low hydrogen MMA rod that is designed specifically for weathering steels such as Corten.

Because of the above if you get these rods damp and require to rebake them then it does require a higher heat for a slightly longer than normal time. 300 to 350 degrees C for 1 to 2 hours.

These rods are made in the UK.

A low hydrogen, basic flux coated electrode on a low carbon mild steel core wire with an extruded moisture resistant chemically basic flux which has controlled iron powder addition. The moisture resistant coating gives a very low weld metal hydrogen levels. The electrode recovery rate in respect to the core wire is approx. 120%. Smooth arc, low spatter, easy strike and restrike. The electrode is mainly used for weathering steels containing a similar controlled addition & is claimed to offer a threefold improvement in corrosion resistance compared with plain C, Mn steels. The weld metal also resists preferential corrosion in sea water, particularly in arctic waters high in oxygen & salinity,

& has applications for welding micro alloys & carbon manganese steels in ice breaker vessels & offshore structures. Applications also include architectural structures, bridges & exhaust gas flues. Materials to be welded include Corten A, B1 (b. steel, US Steels) and other proprietary designations. BS4360 Grade WR50A to WR50C, ASTM A588 Grades A, B, C, K. Din 1.8960, 1.8961, 1.8963.

| Weight | N/A |

|---|---|

| Thickness | 2.5mm, 3.2mm |

You must be logged in to post a review.

Reviews

There are no reviews yet.