Steel is an incredibly useful material that comes in all shapes, sizes and types. It is everywhere, from the cutlery we use, the kitchens that feed us, the hospitals that keep us well to the homes we live in. It’s an amazingly flexible material with literally thousands of uses.

But how much do you know about steel?

Today, we’re going to discuss the four main types of steel, their relative properties and popular uses for each. By the end, you’ll know as much as you’ll ever need to know about this amazing material!

The 4 main types of steel

There are four main types of steel. They are; carbon steel, alloy steel, tool steel and stainless steel. One we have all very likely heard of. The other three may be something of a mystery.

Of those four types of steel, there are over 3,500 different grades covering just about every steel and alloy mix imaginable.

While steel itself is always a mixture of iron and carbon, the other elements and the amounts in which they appear in the steel determines its grade.

For now, let’s stick with those four main types.

They are:

Carbon steel

Carbon steels contain trace amounts of alloys and account for around 90% of total steel production. The material is categorized into three distinct types, low carbon steel, medium carbon steel and high carbon steel. Each is differentiated by the amount of carbon within the steel.

- Low carbon steel contains up to 0.3% carbon

- Medium carbon steel contains 0.3-0.6% carbon

- High carbon steel contains over 0.6% carbon

Low carbon steel is often used for rivets, wire, stamped steel products, pipes, machinery, surgical implements, structural components and appliances.

Low carbon steel is cheap to produce, strong and readily available. It is the most common type of steel in production. It can be further strengthened by carburising.

Carbon steel is known for its low cost, low hardness, mild strength, high toughness, ductility and weldability. It can also be machined easily.

Alloy steel

Alloy steel is manufactured using steel and a range of alloys including aluminium, chromium cobalt, molybdenum, nickel, tungsten and vanadium. Each alloy component adds a different property to the steel, offering almost limitless variations.

Alloy steel is difficult to classify because of the sheer range and variety of alloy mixes possible.

The material tends to be expensive due to the more intensive manufacturing process so isn’t as popular as carbon steel. You will often find alloy steel in car parts, electrical equipment, power generators, electric motors, pipelines, ship hulls and a range of other applications.

Alloy steel can be carburised, meaning it has a hardened surface or through-hardened, that has been thoroughly hardened.

Tool steel

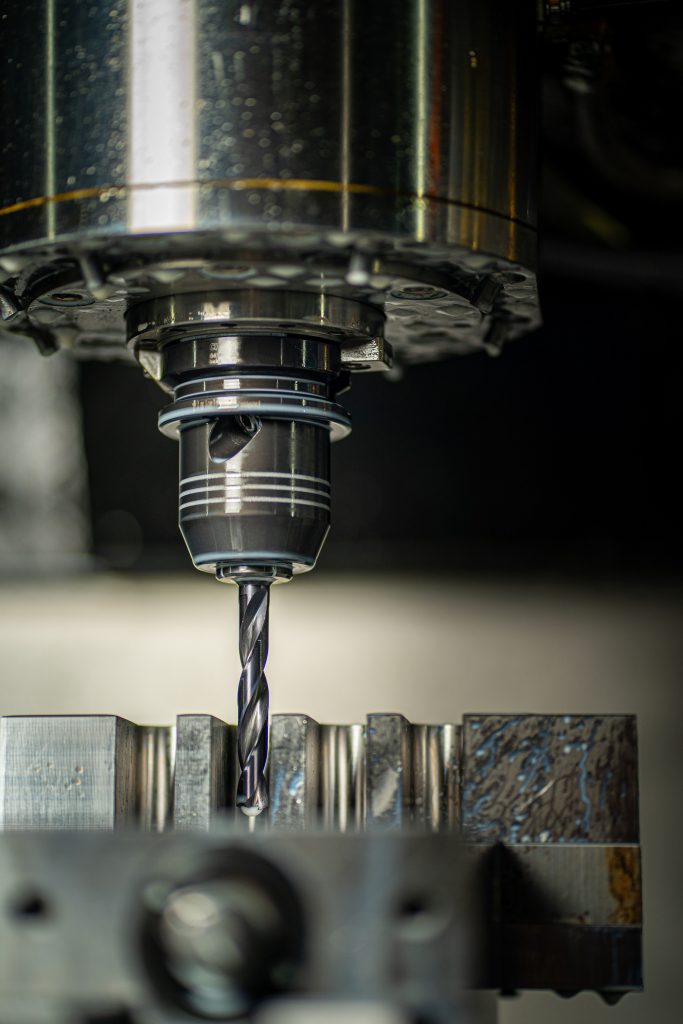

Tool steels contain alloys like tungsten, molybdenum, cobalt and vanadium in varying quantities. As the name implies, this type of steel is often used in tools and tooling thanks to its hard wearing properties and for being impact resistant.

Tool steel uses varying quantities of those alloys to create very strong materials that are also relatively cheap.

You will find tool steels in tools, industrial tooling, drills and drilling equipment, cutting equipment, rods, rails, wires, pipes, sheets, strips, valves, fittings, flanges and many commercial or industrial uses.

Stainless steel

Stainless steel is probably the best known steel. Stainless steel is made up of iron, chromium, nickel, manganese and copper. It has between 10-30% chromium which gives it that shine and resistance to corrosion it is so well known for.

There are three main types of stainless steel:

- Austenitic – Which is not magnetic and cannot be heat treated. Austenitic steel is the most common and can be found in utensils, food preparation equipment, food processing equipment, piping and many industrial uses.

- Ferritic – A type of stainless steel with nickel, chromium, carbon and other alloys. It cannot be heat treated but can be cold worked.

- Martensitic – Martensitic steel includes between 11-17% chromium, less than 0.4% nickel and up to 1.2% carbon. This steel can be heat treated and is magnetic. You will often find it in kitchen utensils, knives, surgical equipment, cuttings tools and products where hardness is required over other characteristics.

Stainless steel comes in over a hundred different grades covering all areas of manufacture and products. The steel grading system is both simple and complex and includes systems from British Standards, International Organization for Standardization (ISO), European Standard (EN) and other organisations.

We typically use the AISI/SAE grading system that uses three numbers. For example, 316 stainless steel. Grading on its own would take up more than one blog post so we’ll leave it there!